Due to popular demand we are proud to announce the addition of the “Side Inlet Sanitary Tee” to our list of recognized fittings. The Side Inlet Tee provides a convenient way of venting an additional fixture into a soil stack. QuickPlumb can now recognize these fittings. Dimensions of each port is included in the update so that the pipe cut list will continue to return the correct pipe lengths. To download the update in Windows 10 simply locate QuickPlumb in the start menu (the button in the lower left corner of your screen) and click the drop down arrow to the right of the title. Choose the “Check for updates” option. This will show the details of the update. You will be given the option to update now or be reminded later. You may view a short video showing how to use this fitting by clicking here.

Category: Articles

WARNING! – These are NOT your Dad’s Compression Angle Stops

We got the call from our builder to head to their new house asap. It was about 8 am and there was a “walk through” with the homeowner at 9 am. When I walked into the basement entrance there was water dripping from the ceiling and the builder’s sales rep was there with the construction foreman. They directed me up to the second floor where the leak occurred. We headed up the stairs passing the 1st floor where the living room ceiling was dripping with water. It was the longest flight of stairs I had ever traversed. It seemed to take a week to get to the top. There was a small pond on the 2nd floor. In the hall bathroom behind the toilet was an open ended stubout where angle stop used to be. The compression angle stop was dangling from the toilet by the supply tubing. If you ever wondered how long it takes for a 1/2 inch pipe to fill a house with water I can tell you. About 2 minutes.

We had made it clear to the foreman that our policy is to turn the water to the house off at the end of each day in case there was a leak somewhere. We would rather find a leak during the day than discover a flood in the morning. On the day of this flood they had arrived and turned the water on only to realize the leak when the water started dripping from the ceiling.

The angle stop had pushed itself off of the copper stubout due to the compression ring not compressing around the pipe. In recent years brass with lead in it has been removed from the market where potable water fittings are concerned. As a result the lead free brass is noticeably more rigid and less malleable. It takes more torque to force the brass ferrule into a compressed state forming a water tight seal around the pipe. The installer in this case thought he had a good watertight seal after turning the compression nut on the angle stop to the torque he was accustomed to. The same torque would have worked fine with the old leaded brass ferrules but not with the lead free brass.

Brasscraft angle stops come with instructions to turn the compression nut hand tight plus 3/4 of a turn. With the new lead free brass this can feel like quite a bit of torque. You will likely need very large wrenches to achieve the required torque to get 3/4 of a turn.

It is my hope that this article will save someone else the anguish of a flood caused by this phenomenon.

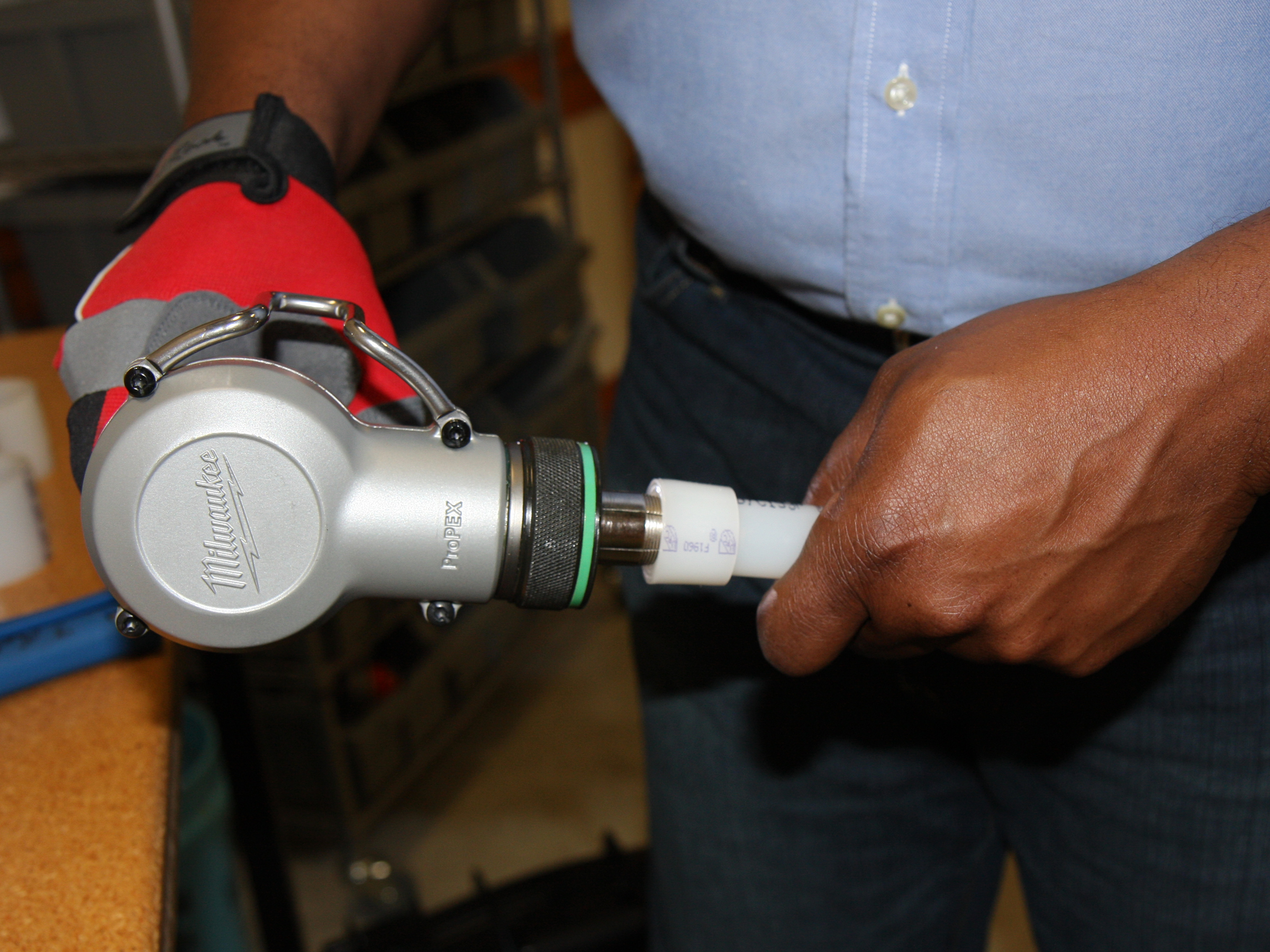

Uponor pipe is now supported by QuickPlumb software.

QuickPlumb software now supports Uponor pipe and fittings. You can draw multiport tees and connect them to your fixtures. QuickPlumb will add them to your material lists ready to be sent to the supply house. One of the benefits of using Uponor is the ability to reduce the number of fittings thereby reducing material costs and labor.  With Quickplumb you will get an accurate count of all your pipe and fittings every time. You can also use the pipe sizing feature to automatically size every segment on your plan using universally accepted engineering standards. We at Epiphany Software Corporation are proud to support such a fantastic product and we look forward to making the design aspect as easy as possible for your plumbing design team. Download a free 30 day trial of QuickPlumb and see for yourself how easy plumbing with Uponor can be.

With Quickplumb you will get an accurate count of all your pipe and fittings every time. You can also use the pipe sizing feature to automatically size every segment on your plan using universally accepted engineering standards. We at Epiphany Software Corporation are proud to support such a fantastic product and we look forward to making the design aspect as easy as possible for your plumbing design team. Download a free 30 day trial of QuickPlumb and see for yourself how easy plumbing with Uponor can be.

Legislative and Regulatory Update – by Dan Hilton, ASA Director of Government Affairs

Legislative and Regulatory Update Tariffs catch world off guard. March 1st was probably one of the wildest days in an already wild Washington, D.C. On the preceding evening, the Washington Post broke a news story that the president was set to announce tariffs on steel and aluminum the following day. That’s where the confusion began. At the start of the week, on February 26th, the consensus among D.C. insiders was that the president would be making an announcement in the first full or second week of March. With a special election taking place in the suburbs of Pittsburgh, home to many of America’s remaining steel companies, many believed the president may use this announcement to get out the vote for the candidate in his party. But we were wrong! If the rumors are to be believed, an internal White House meeting on the general issue of trade took place that Wednesday (Feb. 28), and there was no mention, let alone any planning for this looming announcement. Those of us that had only just began working this issue woke up Thursday to the news that while the president had until the end of April to make a decision, it was coming that day! More rumors persisted, including a report by an “unnamed source” that claimed Commerce Secretary Wilbur Ross and influential trade advisor Peter Navarro had orchestrated the Thursday meeting with executives from leading steel and aluminum companies. Apparently, without the knowledge, nor clearance by the White House Chief of Staff, who customarily clears who and who does not warrant a meeting with the President of the United States. Because of this ongoing uncertainty, Thursday’s real-time reporting was that the announcement of tariffs would be postponed, and the meeting with steel industry leaders would just be a quick grip and grin … until the president spoke up and announced “we’re going to have tariffs of 25% on steel and 10% on aluminum.” Financial markets began dropping like a rock and users of these items immediately sprang into action. With the slight hope that this was an unofficial announcement, there was a furious 24 hours of issuing statements, calls to action and grassroots letters to the White House asking them to rethink this decision. While reports and rumors continue to swirl, we can only believe what we’ve heard directly from the president’s mouth, which at times differs from that which is said by his advisors, and the final official recommendations that come from his office. Though he’s shown no signs of going easy on an ally like Canada, he has said on March 5th that Mexico and Canada could get a reprieve from these tariffs if they were amenable to re-writing the North American Free Trade Agreement or NAFTA. – by Dan Hilton, ASA Director of Government Affairs

http://www.asa.net/

We’re all about plumbing

Epiphany Software Corporation was established by people who have plumbing design backgrounds and work closely with plumbing contractors so we know first hand the challenges that face plumbing professionals in the field as well as in the office.Many of our staff have plumbing design backgrounds. We are dedicated to providing the most complete software tools available so that you can offer the very best product to your customers as efficiently as possible. As we all know, there is no substitute for proper planning and with QuickPlumb you can relax knowing that your jobs will come together just as planned.

My Beginnings in Plumbing

I started plumbing houses about 25 years ago. Gone were the days of lead and oakum and galvanized water service piping. It was a pretty good time to get into the plumbing business. I remember my first North Carolina plumbing code book. It was a small green paperback around 8 x 10 inches. My first plumbing job was my own house that I built in 1989.

My first experience with pipes was while working for a water treatment company installing water softeners and filters. I was persuaded to get into the plumbing business by the chief plumbing inspector for New Hanover County, Kenneth Fowler. I got a call on my bag phone (about the size of a shoe box for you young readers). It was my secretary. She said Mr Fowler wants you to give him a call and he’s mad. That was one of the hardest calls I have ever made. He wanted to know why there was no permit for the water softener I had installed in a new house. I had to explain that I did not have my license yet but I was working on it. Luckily the plumbing contractor on record for that house allowed me work under his permit on that job. So I was off to the races to get my license. I took both the residential test and the commercial. I figured I stood a chance of passing one even I failed the other. So for the next year or so I ran my business without incident. The water treatment business got to be more and more of a headache so I studied the plumbing business for the next year or so. I got my first lucky break when I landed 2 apartment/condo jobs.

It’s funny how things work out. The plumbing business has been very rewarding. There is a good living to be made for anyone willing to put in the effort. Two babies and 25 years later I can say that I a grateful to Mr Fowler for pointing me in the right direction.

Good service-congeniality included

Hi Blog fans!

I want to take a minute to remind everyone the importance of knowing what to say or not to say when you are at a customers home or place of business doing service. Just as important as knowing your trade, you should also be choose your words carefully and thoughtfully. I am writing this article because I had an experience recently that made the homeowner very upset. While I was at her home there was another tradesman doing some work on the heating system. She asked if he thought it was worth the investment to convert from propane to natural gas to heater her home. His reply was “How old are you?”. I started to head for the door when those words left his mouth but I still had business to take care of. When she refused an answer to that he immediately followed with “Do you expect to live another 30 years?” She replied “No”. He went on to explain that the return on her investment would not be realized for some time to come and that she would be just as well off to leave things as they are. By this time I was sneaking towards the door as quietly as possible. I thought “Thank goodness he doesn’t work for our company.”

Let’s take a look at the insinuations he was making without even realizing it. First, she appeared to be in her early 70’s and no self respecting southern girl is going to give her age. Second, he had no idea what physical challenges that she might be facing and would rather not discuss with the hvac service guy. As it turned out I later found out that she had been battling cancer. Most importantly, he assumed that she was only concerned about herself and if the system continued to be more expensive to run after her death then “who cares?”

I’m sure most service technicians are more congenial than this guy but it might be worth the effort to train your service team on manners and proper etiquette.

Pipe sizing tool is now included!

The long awaited pipe sizing tool for water distribution is now available with QuickPlumb Pro 5.0. Just fill out the form for a fully functional free trial on our home page and try it for yourself. How to videos are on the way.

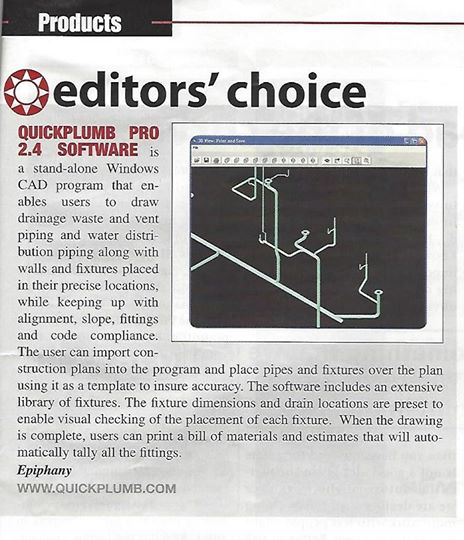

QuickPlumb “Editors Choice” Contractor Magazine!

QuickPlumb by Epiphany Software Corporation makes “Editors Choice” in Contractor Magazine! Thank you guys and girls at Contractor! You are the best!

There is no easier plumbing software on the market. With it’s ability to count each and every fitting so that you know the correct material quantities will be ordered and you will not be caught short of supplies the cost on the software will more than pay for itself. Think of how devastating it is when you arrive on the job site after the concrete has been poured only to find that there was an error. The plumbing stub-ups are in the wrong location!

Many of the challenges that arise in the business of plumbing contracting are overlooked by the majority of software vendors. Some of these include getting accurate coordinates for plumbing stub ups in slab construction. This is a critical element of any job because of the consequences of a pipe that is out of place and needs to be moved. The concrete will need to be cut and enough room will be needed to reroute the pipe to the correct location. This makes an unsightly mess on any jobsite and the general contractor is never happy when his freshly poured and finished concrete is in pieces. This is one of the main focuses of QuickPlumb software. Each fixture that is placed on the plan has plumbing stub up locations entered which follow it where ever it is placed on the plan. When you select View>Fixture Coordinates form the top menu bar dimension lines are extended to the reference lines that you can insert anywhere to represent such things as the edge of forms. Using these dimensions allows you to double check the stub up locations so that they are in the correct place. This along with the pipe cut list minimizes the possibility of mistakes during the slab phase of the plumbing project.

QuickPlumb saving and moving project files.

Projects that you save to My Documents folder consist of one *.qpl file and a .bmp file for each of the plans you import into QuickPlumb. The *.bmp files will have the same name as the *.qpl file except that they will have a number from 0 to 5 appended to the end of the file name which represents the floor level that they belong to.

For example a file named “My Project” with 3 plans imported would consist of the following files:

My Project.qpl

My Project0.bmp

My Project1.bmp

My Project2.bmp

You can move these project files from one location to the other as long as you please all of them in the same folder.

There is no easier plumbing software on the market. With it’s ability to count each and every fitting so that you know the correct material quantities will be ordered and you will not be caught short of supplies the cost on the software will more than pay for itself. Think of how devastating it is when you arrive on the job site after the concrete has been poured only to find that there was an error in the layout and the plumbing stub-ups are in the wrong location!

Many of the challenges that arise in the business of plumbing contracting are overlooked by the majority of software vendors. Some of these include getting accurate coordinates for plumbing stub ups in slab construction. This is a critical element of any job because of the consequences of a pipe that is out of place and needs to be moved. The concrete will need to be cut and enough room will be needed to reroute the pipe to the correct location. This makes an unsightly mess on any jobsite and the general contractor is never happy when his freshly poured and finished concrete is in pieces. This is one of the main focuses of QuickPlumb software. Each fixture that is placed on the plan has plumbing stub up locations entered which follow it where ever it is placed on the plan. When you select View>Fixture Coordinates form the top menu bar dimension lines are extended to the reference lines that you can insert anywhere to represent such things as the edge of forms. Using these dimensions allows you to double check the stub up locations so that they are in the correct place. This along with the pipe cut list minimizes the possibility of mistakes during the slab phase of the plumbing project.